SYSTEM COMPONENTS

Pipes

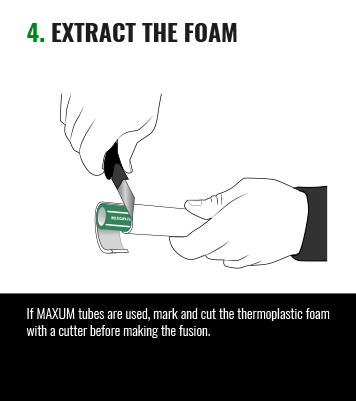

MAXUM S 3.2

The continuous innovating spirit of IPS has allowed for the development of the ideal pipe for hot water installations and harsh climate: MAXUM S 3.2. Its exclusive lining and closed cell thermoplastic foam insulation achieves the highest thermal and mechanical resistance with the smallest external diameter of the market , thus avoiding big gutters.

Multilayer IPS Fusion S 3.2

The S 3.2 pipe, which corresponds to a rated pressure of 20 bar. In its characteristic inner white layer, the Random Copolymer has antioxidant additives which extend its operating life at high temperatures. Externally, the white lines simplify its use on-site.

IPS Fusion

Pipe especially designed to conduct cold water, it corresponds to a rated pressure of 12,5 bar. It has external white stripes which simplify the installation.