ABSOLUTE SECURITY

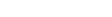

Medium-density polyethylene-coated steel piping

system for heat fusion welding.

VANTEC+ meets the requirements of the NAG E 210 standard set by IGA (Instituto del Gas Argentino) as the certifier organization, approved by ENARGAS (Ente Nacional Regulador del Gas Argentina) and by IBNORCA (Instituto Boliviano de Normalización y Calidad).

VANTEC+ is included in the IPS quality management system, certified under ISO 9001 standard endorsed by IRAM – IQ Net.